©2023C&Bsrl

CAPABILITIES

OPERATING PROCESS

TECH

FLEXIBILITY

CREATIVITY

CAPABILITIES

THE C&B SKILL MIX

Technologies are important, but the real enablers remain the people with their skills;

the ability to adapt to contexts in rapid change, as well as the intuition, creativity and

experience of our managers, are part of those soft skills, that machines do not yet possess.

C&B

OPERATING PROCESS

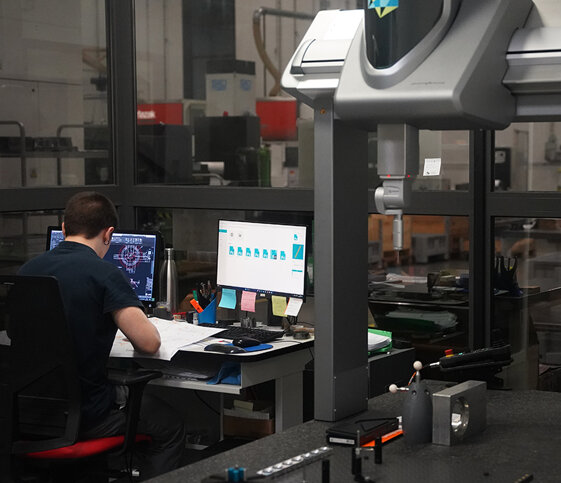

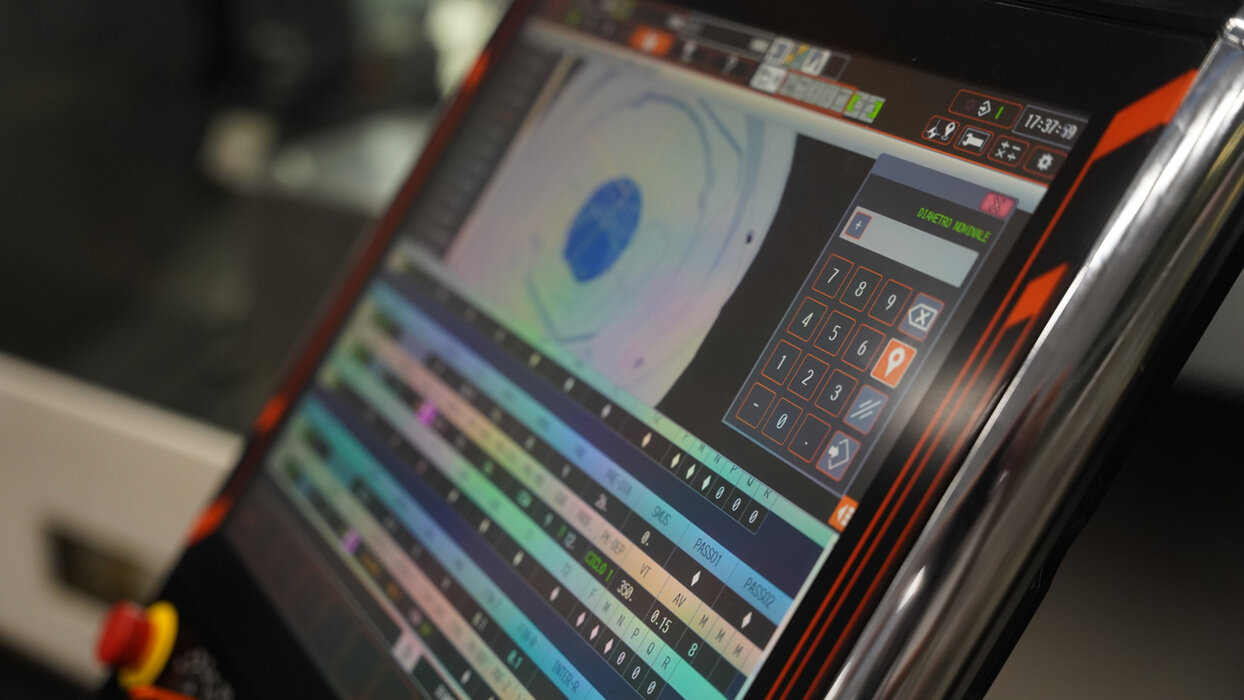

Merging the real and virtual worlds. Through the use of advanced production

and production monitoring software systems, it is possible to check in advance

for problems with the machining operations to be performed. This makes it

possible to optimize machine setup operations and production start-up costs.

Merging the real and virtual worlds. Through the use of advanced production

and production monitoring software systems, it is possible to check in advance

for problems with the machining operations to be performed. This makes it

possible to optimize machine setup operations and production start-up costs.

The ability to manage every job order, each time studying ad hoc solutions

for the needs of each individual customer, ensuring the highest quality from

the eventual design phase, often done in collaboration with the client, to the

production and delivery of the finished product-this is the C&B operating process.

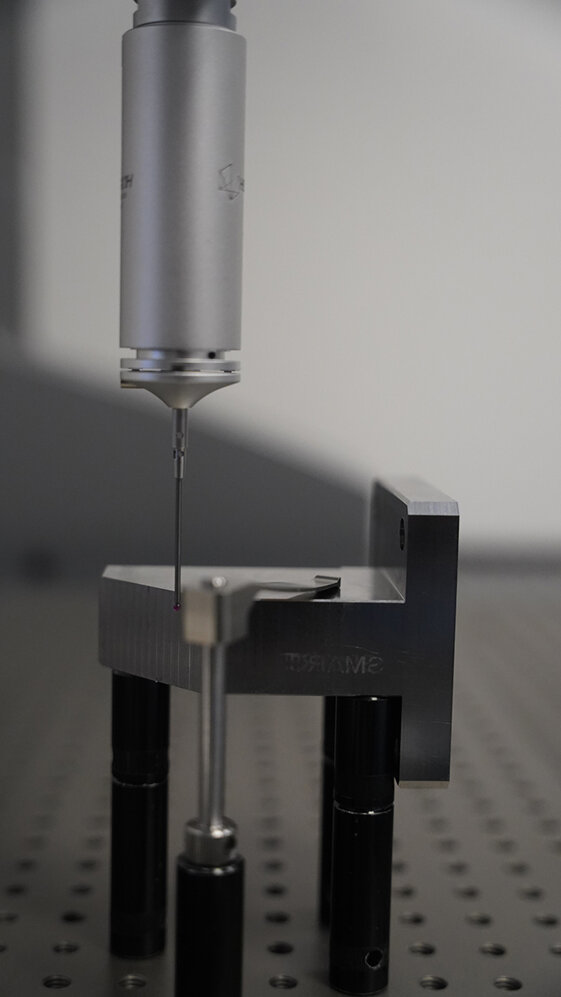

C&B MULTITASKING

DONEINONE

After years of fruitful cooperation with MAZAK, a leading manufacturer of

advanced technological solutions such as multitasking and 5-axis machining,

following our future-oriented business plan, we have taken another step forward.

First in Italy, we have installed the latest of the brand new DONEINONE machines

capable of realizing all machining processes with a single machine setup,

the Integrex 450H ST (10 controlled axes).

OPERATING PROCESSES

INTERNAL

TURNING

MILLING

MULTITASKING