©2023C&Bsrl

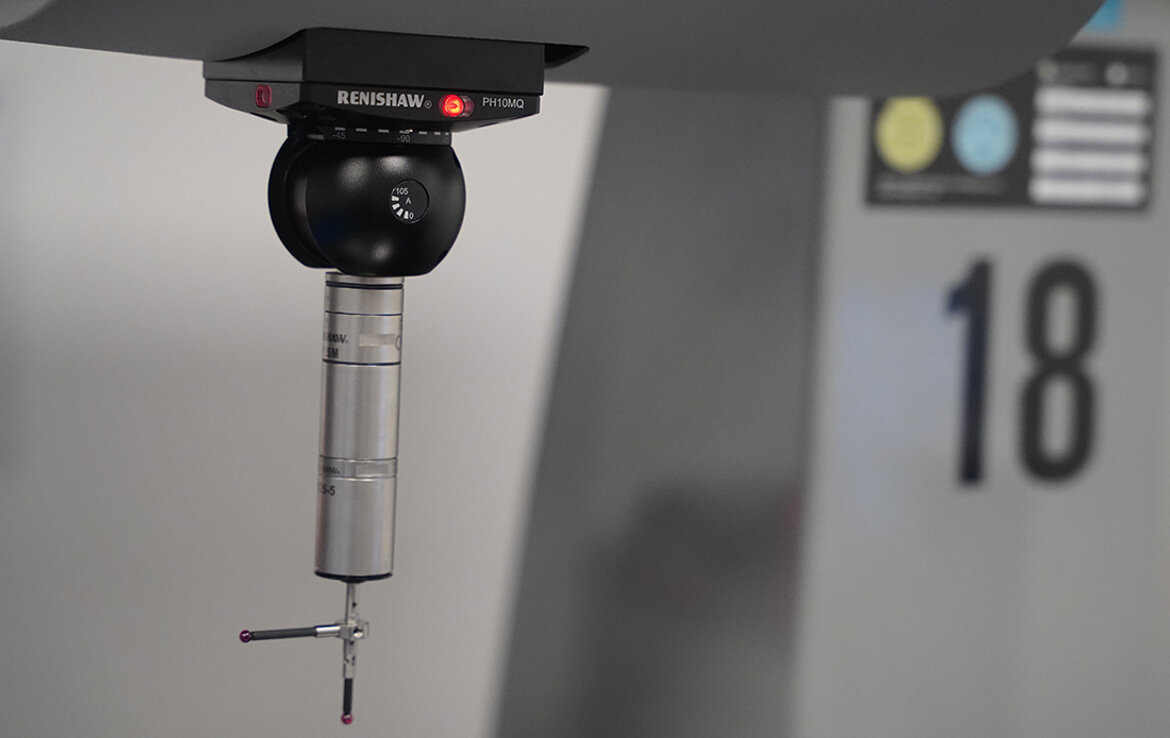

CMM

COORDINATE MEASURING MACHINES

CMM

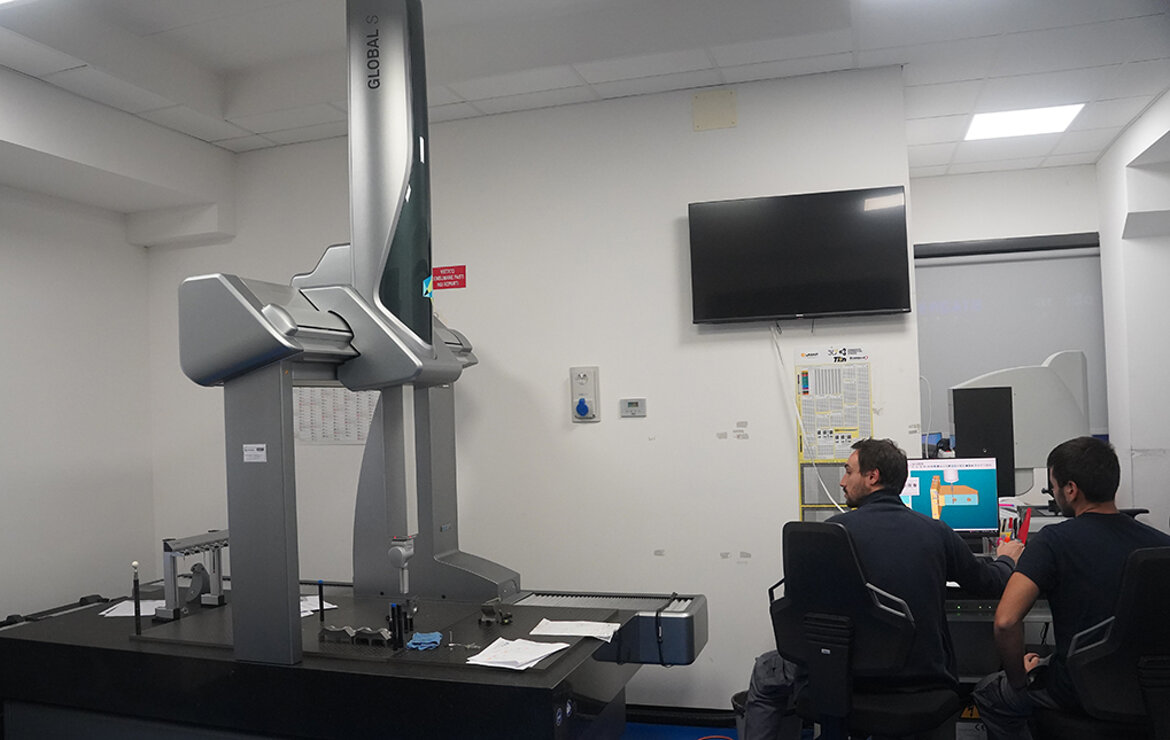

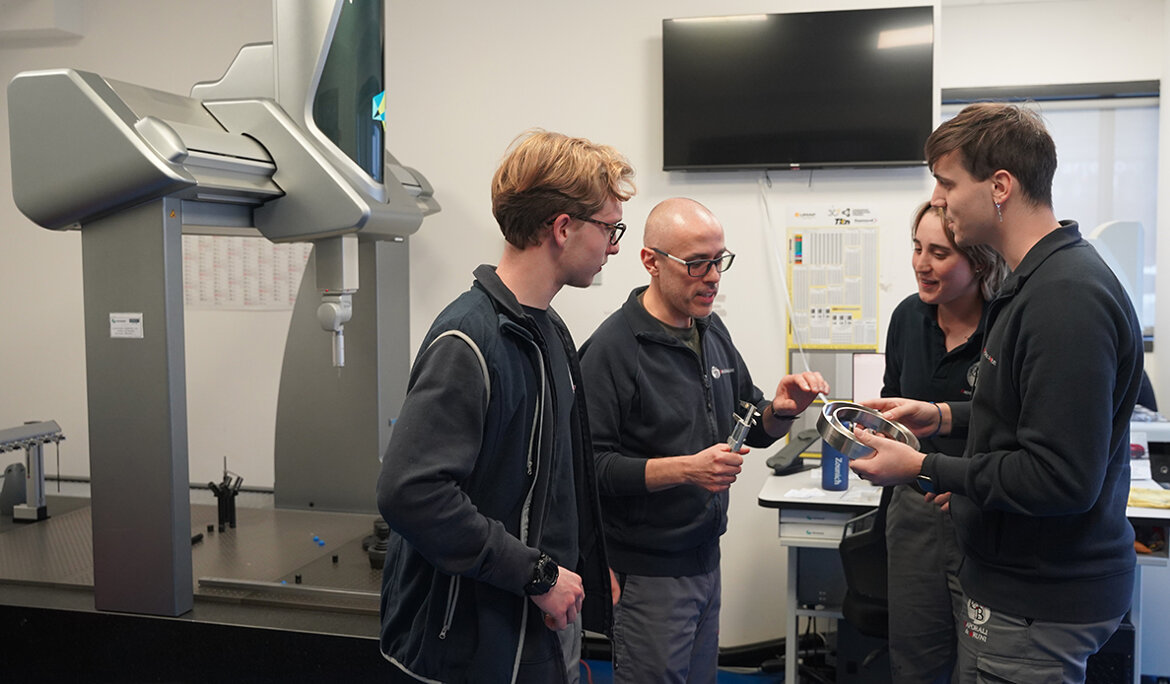

CMMs are mainly used to test parts or assemblies and determine whether they conform to the original design specifications. They are integrated into quality assurance or control workflows to inspect the dimensions of manufactured components, thus preventing or resolving quality issues.

QUALITY CONTROL

Guarantee of direct support to production departments with an internal metrology service; this department supports production during the start-up phase of processing from the first piece to mass production. Dimensional CMM inspections on parts being processed with issuance of a certificate/Test Report of testing. Re-engineering activities up to the complete production process are also possible.

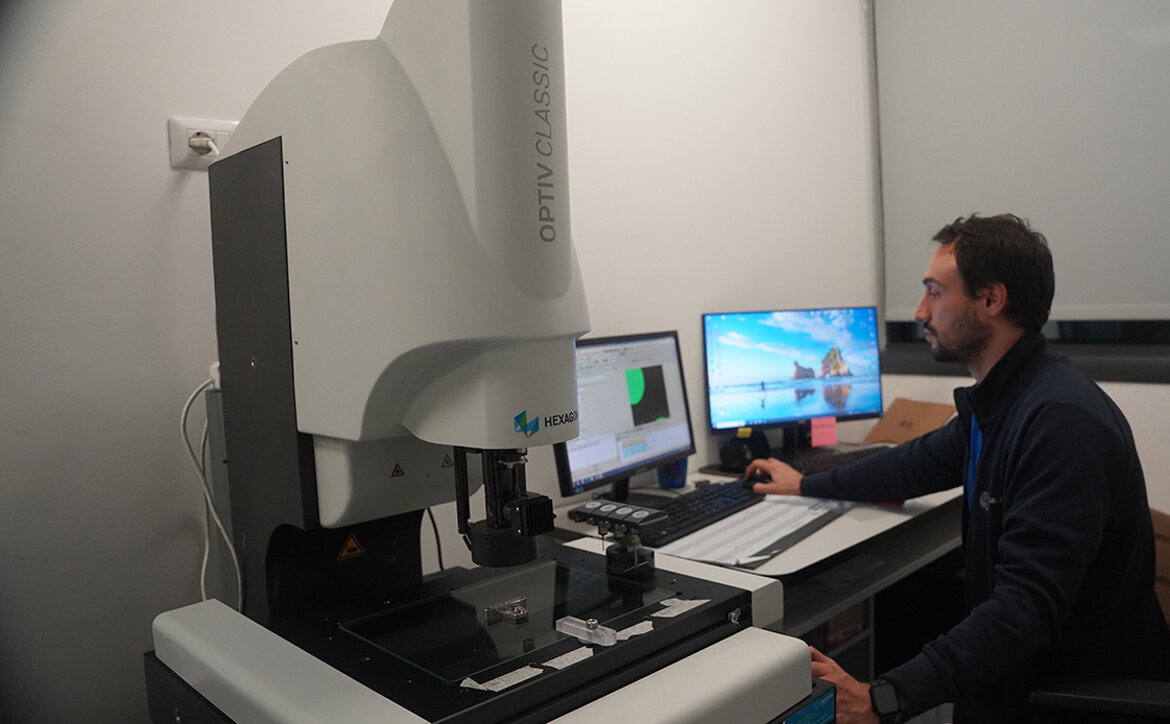

ROOM

METROLOGICAL

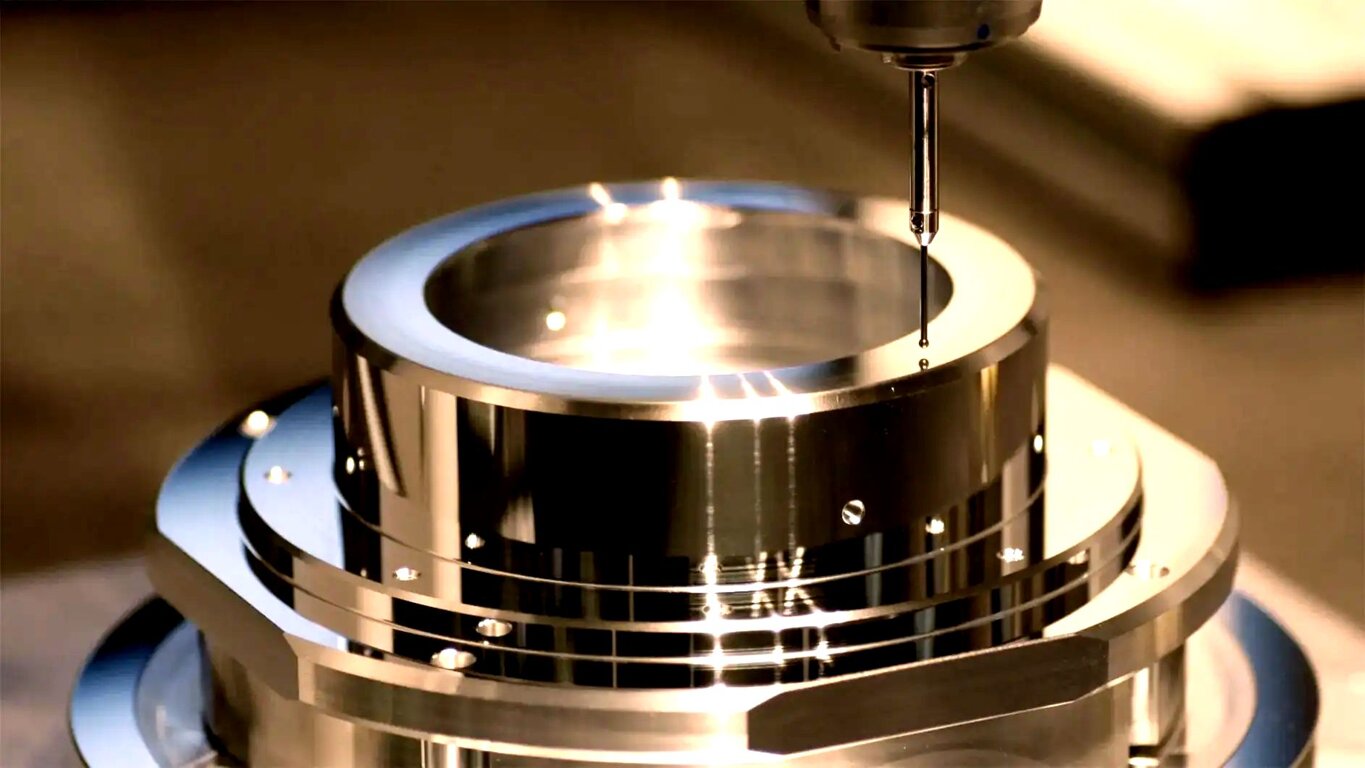

Quality control is our flagship, thanks also to our metrology room with constant temperature and isolated from vibrations, equipped with the best measuring instruments.

MACHINERY MEASUREMENT

The use of CMMs offers numerous advantages compared to conventional measuring instruments.

These advantages include greater accuracy, speed, and reduction of human errors.

LIST MACHINERY

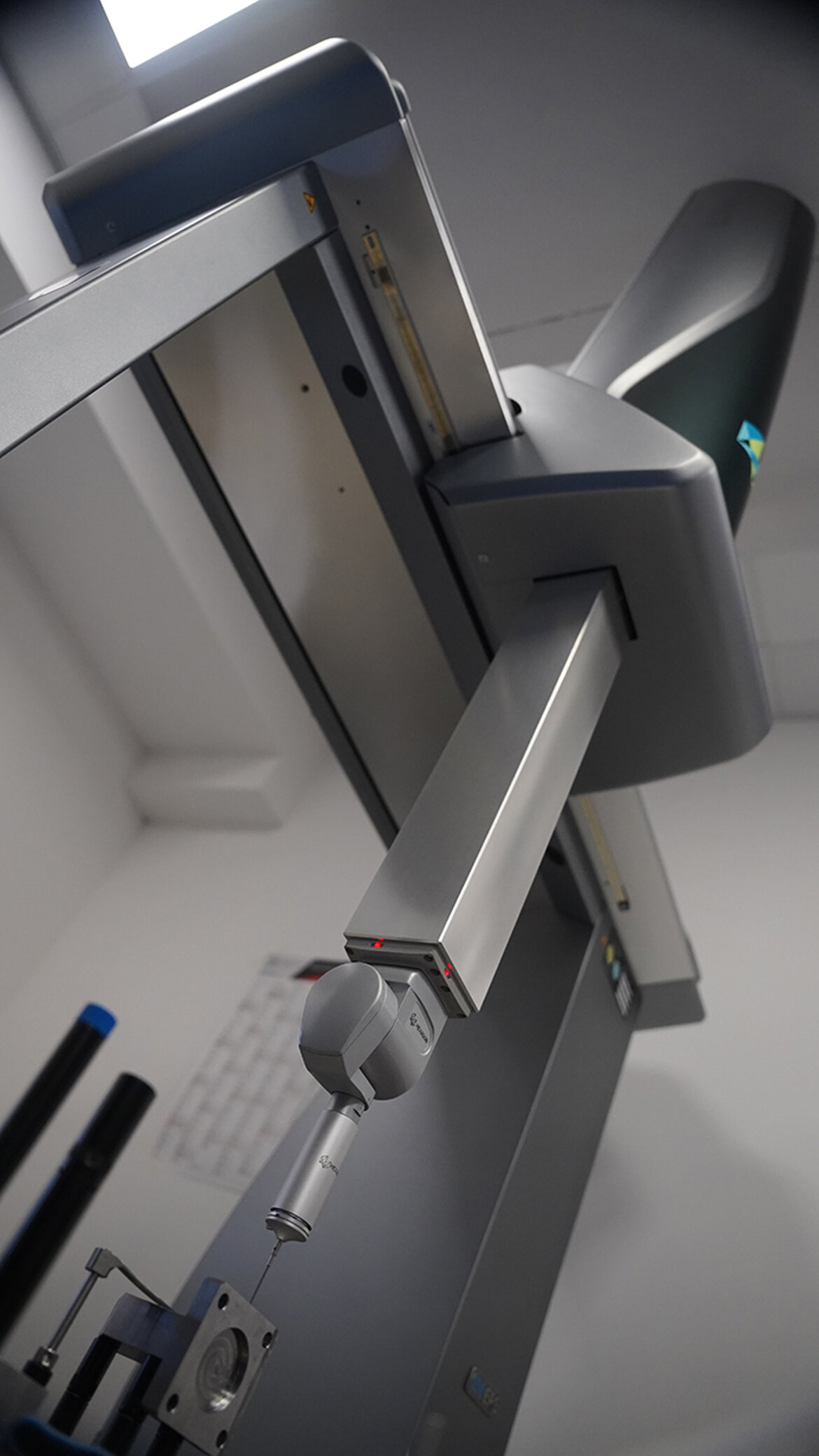

1 DEA GLOBAL STATUS 7107 CMM measuring machine with rotary head and continuous scanning

2 HEXAGON GLOBAL S BLUE 9158 CMM measuring machine with rotary head and continuous scanning

1 HEXAGON OPTIV CLASSIC 322 optical measuring machine

1 Hexagon 3D Laser Scanner measuring arm