©2023C&Bsrl

OPERATING PROCESS

TECH

FLEXIBILITY

CREATIVITY

ABILITY

THE MIX OF C SKILLS&B

Technologies are important, but the real enabling factors remain people

with their skills. The ability to adapt to rapidly changing contexts,

as well as intuition, creativity and the experience of our managers, are part

of those soft skills that machines still do not possess.

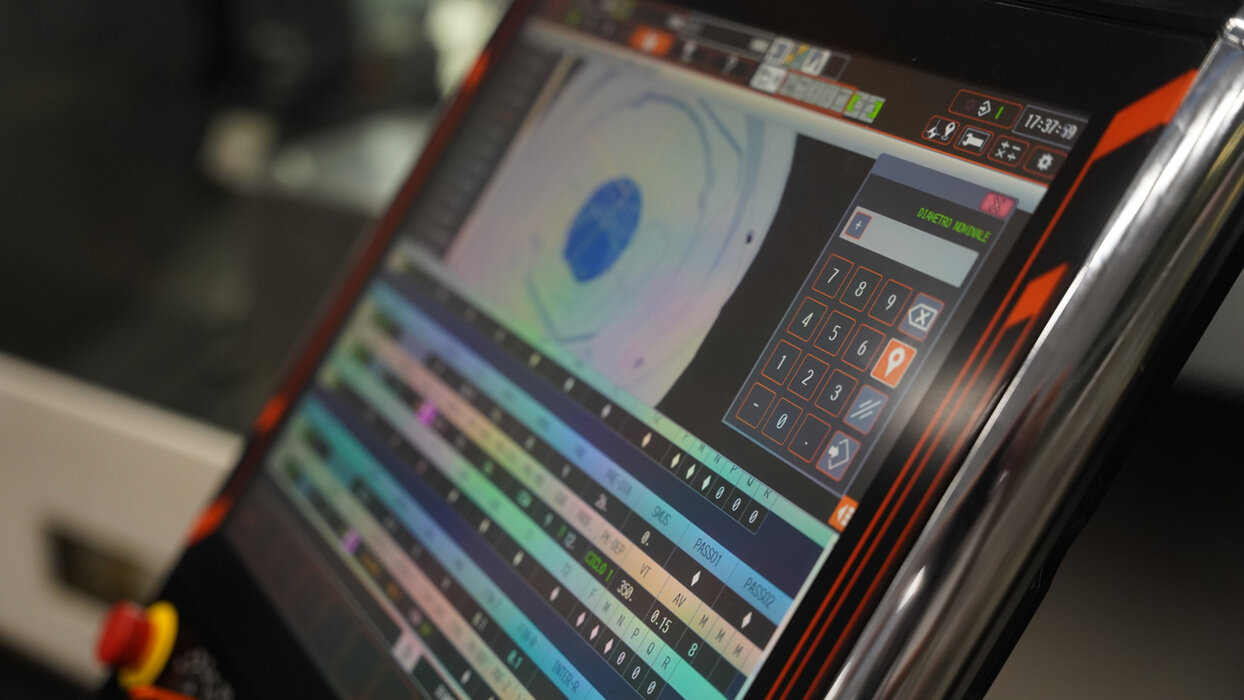

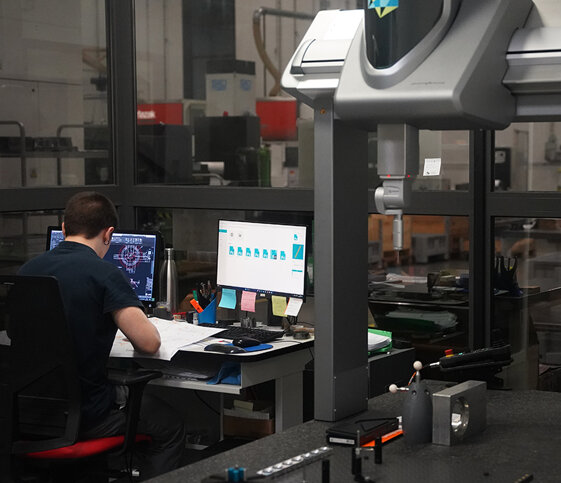

Unite the real and virtual world. Thanks to the use of advanced software systems

for production and production monitoring it is possible to check in advance

the issues related to the processes to be carried out. This allows you to optimize

machine setup operations and production start-up costs.

The ability to manage each job, always studying tailor-made solutions

for the needs of each individual client, guaranteeing the highest quality from the possible

design phase, often carried out in collaboration with the client, to the production

and delivery of the finished product, this is the operational process C&B.

C&B MULTITASKING

DONEINONE

After years of fruitful collaboration with MAZAK, a leader in the production of advanced technological solutions such as multitasking and 5-axis machining, following our company plan aimed at the future, we have taken a further step forward. First in Italy, we have installed the latest of the brand new DONEINONE machines capable of performing all machining processes with a single machine setup, the Integrex 450H ST (10 controlled axes).

PRODUCTION PROCESSES

INTERNAL

Our production skills are diversified in our turning department thanks to the multiple capabilities and availability of our infrastructure. We carry out bar machining for medium-high production batches and secondary machining with milling on technologically advanced components.

Production is also structured around another concept of processing, which can essentially be classified in terms of resources and technological capabilities for 3-4-5 axis milling. Production planning is developed and analyzed based on the key characteristics of each component in production, while still maintaining a standard configuration for the overall management of customers.

Multitasking machine tools represent the most complex and diverse configurations currently available on the market. Unlike traditional CNC machining centers, multitasking machines use tools simultaneously on one or more spindles, often in a synchronized manner.

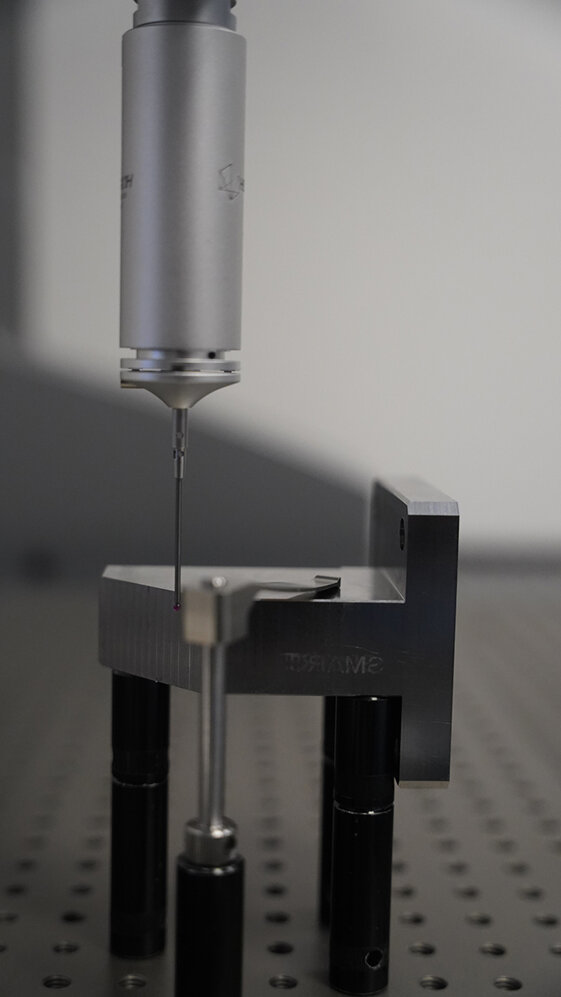

QUALITY CONTROL

Guarantee of direct support to production departments with internal metrology service. Dimensional CMM inspections on parts in processing with issuance of certificate/Test Report. Possible re-engineering activities up to the complete production process... Find out more

PROCESSES PRODUCTIVE

EXTERNAL

Galvanic treatments

Chemical nickel plating (MIL-C-26074)

Aluminum chromating (MIL-DTL-5541 TypeI/II Class 1A-3)

Zinc plating (QQ-Z-325 B Type II-class 2)

Black chromating (MIL-DTL-14538)

Stainless steel passivation (QQ-P-35)

Powder and liquid painting Sandblasting(QNT-0081)

Micro shot peening

Heat treatments

Laser marking

Insert assembly

WORKABLE MATERIALS

FERROUS ALLOYS

QUENCHED AND TEMPERED STEELS

CASE-HARDENING STEELS

STEELS FOR COLD STAMPING

STAINLESS STEELS

AUTOMATIC STEELS

COPPER ALLOYS

ALUMINUM ALLOYS

PLASTIC MATERIALS

©2023C&Bsrl